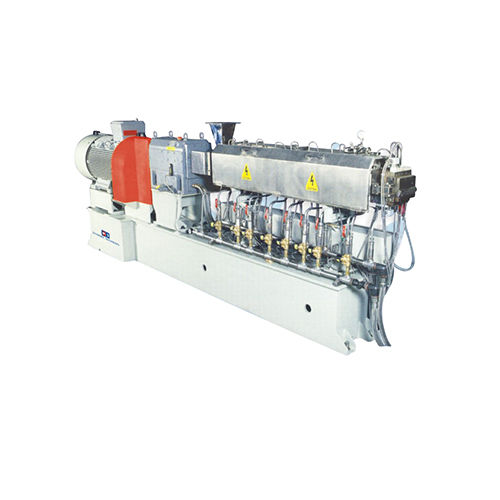

Co-Rotating Twin Screw Extruder Machine

Co-Rotating Twin Screw Extruder Machine Specification

- Production Capacity

- 180-600 kg/hr

- Machine Type

- Twin Screw Extruder

- Control System

- PLC Based

- Connectivity Options

- Ethernet, USB Interface

- Operating Temperature

- 10C - 270C

- Accuracy

- 0.02 mm

- Lubricating System

- Automatic

- Voltage

- 380 V

- Model No

- CTSE-75

- Cooling System

- Water Cooling

- Motor Power

- 75 kW

- Frame Type

- Heavy Duty Welded Frame

- Noise Level

- 80 dB

- Drive

- AC Motor with Inverter

- Power Rating

- 60-90 kW

- Plastic Processed

- PP, PE, ABS, PVC, PET, and engineering plastics

- Features

- High torque, modular construction, easy maintenance, energy efficient

- Frequency

- 50 Hz

- Product Type

- Co-Rotating Twin Screw Extruder Machine

- Technology

- CNC

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 60 kW

- Pressure

- Up to 30 MPa

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 4000 x 1200 x 2000 mm

- Weight (kg)

- 2100 kg

- Color

- Blue & Yellow

- Usage & Applications

- Plastic compound processing, masterbatch production, polymer blending and pelletizing

- Screw L/D Ratio

- 40:1

- Barrel Heating

- Ceramic Heaters

- Screw Material

- Wear-resistant Alloy Steel

- Gearbox Type

- High Torque, Low Noise

- Feeding System

- Volumetric/Gravimetric

- Screw Diameter

- 65 mm

- Auxiliary Support

- Feeder, Cutter, Water Bath, Pelletizer

- Emergency Stop

- Integrated

- Safety Standard

- CE Certified

- Extrusion Output

- Customizable based on configuration

- Voltage Stabilizer

- Optional

- Installation Service

- Available on-site

- Main Motor Brand

- Siemens/ABB

- Hopper Design

- Stainless Steel with Agitator

- Touchscreen HMI

- Included (7-inch color display)

- Warranty Extension

- Available upon request

- Barrel Material

- High-grade Nitrided Steel

Co-Rotating Twin Screw Extruder Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Co-Rotating Twin Screw Extruder Machine

Co-Rotating Twin Screw Extruder Machine consists of two intermeshing screws that rotate in the same direction within a barrel. These are designed to push the material through the barrel where it is subjected to heat, pressure and shear forces that leads to plasticization and extrusion. Co-Rotating Twin Screw Extruder Machine can be used for various applications including mixing, devolatilization, and compounding of elastomers, thermoplastic materials, and other polymers.

Advanced Construction for Superior Performance

The CTSE-75 employs high-grade nitrided steel barrels paired with wear-resistant alloy screw elements, ensuring exceptional longevity and resilience during continuous operation. Its modular setup allows for rapid configuration changes, making it perfectly suited for processing a wide range of polymers, including engineering plastics. The ceramic heating system provides efficient and precise thermal management throughout the extrusion process.

User-Friendly Operation and Robust Control

Featuring an intuitive 7-inch touchscreen HMI and PLC-based control system, the machine allows for precise parameter adjustments and real-time monitoring. An integrated emergency stop, low-noise gearbox, and energy-efficient AC motor with inverter further streamline daily operation, while Ethernet and USB connectivity offer seamless data management and recipe storage.

Comprehensive Safety and Customization

CE certification, a stainless steel hopper with agitator, and automatic lubricating system underscore the CTSE-75s commitment to operational safety and reliability. Customers can choose between volumetric and gravimetric feeding systems, add a voltage stabilizer, and request warranty extension for added peace of mind and machine longevity.

FAQs of Co-Rotating Twin Screw Extruder Machine:

Q: How does the CTSE-75 Twin Screw Extruder enhance plastic compound processing efficiency?

A: The CTSE-75 features high-torque, co-rotating twin screws and a modular construction, enabling thorough mixing, dispersing, and compounding of polymers like PP, PE, ABS, PVC, and PET. Its precise temperature and speed controls ensure consistent pellet quality and high throughput rates up to 600 kg/hr, reducing processing times and material waste.Q: What materials can be processed using this extruder?

A: This machine can handle a broad spectrum of plastics, including polypropylene (PP), polyethylene (PE), acrylonitrile butadiene styrene (ABS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and various engineering polymers. Its robust build accommodates both commodity and engineering plastic applications.Q: When is on-site installation and commissioning available for the machine?

A: On-site installation and commissioning services are offered as part of the delivery package or upon client request. Scheduling is typically organized at the time of order confirmation, ensuring timely setup and operational training tailored to the customers location within India or for export orders.Q: Where is the CTSE-75 manufactured and exported from?

A: The machine is designed, manufactured, and supplied in India by a reputable exporter, manufacturer, and supplier, ensuring local support and compliance with international standards. It is available for both domestic clients and international export, meeting diverse industry requirements.Q: What is the typical process flow for operation and maintenance?

A: Operation begins with material feeding via the stainless steel hopper with agitator, followed by precise polymer mixing and melting using co-rotating screws. Post-extrusion, the material is cooled using an integrated water bath and then pelletized. Routine maintenance includes automatic lubrication, barrel and screw cleaning, and periodic checks facilitated by modular parts and accessible design.Q: How does the extruder benefit manufacturers in masterbatch and polymer applications?

A: Manufacturers gain consistent product quality, energy efficiency, and flexibility to adapt output for various compounds. The CTSE-75 supports scalable production, improved dispersion of additives, and robust performance under demanding operating conditions, boosting overall productivity and reducing downtime.Q: What auxiliary equipment and customization options are available?

A: Auxiliary support includes feeders, cutters, water baths, and pelletizers. Customers can opt for a voltage stabilizer, tailored feeding system (volumetric or gravimetric), warranty extension, and various on-site service packages to optimize machine utility for specific production needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email